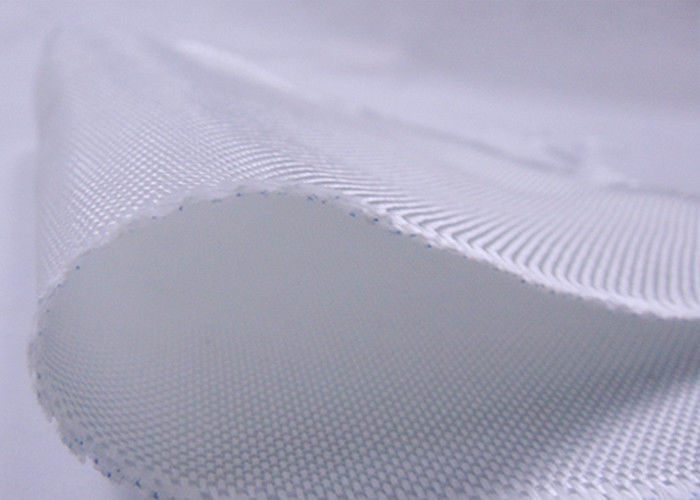

High Tensile Strength Woven Glass Fiber Cloth for Filter Press / Liquid Filter Bag

Quick Detail:

High filtration efficiency ,long service life

Good anti - abrasion

High temperature grade

Anti - acid ,anti - alkali, chemical resistance

High porosity ,good air permeability

Good price quality

Laminated compound , grads counterchange

Description:

Material: Fiberglass

Weight: 800~1250G/M2

Air permeability: 8-15m3/m2. Min

Tensile strength: Warp > 1800N/5X20cm; Weft > 1800N/5x20cm

Elongation: Warp <10%; Weft < 10%

Continuous temperature: 240 C, Instant: 260 C

Finishing: treating

Standard: ISO9001: 2000

Note: The dimension of our product can be custom

Benefits

- High temperature resistance

- Excellent dimensional stability

- High breaking strength

- High cost performance ratio

Disadvantages

- Easy to snap and not extendable

Applications:

Widely uses for carbon black, steel and non-ferrous metal processing, and chemical industry Chemical industry, steel industry, metallurgy, carbon black, power plant and cement.

Specifications:

Glass Fiber Finished filter cloth specification:

Item No. |

LOI (%) |

Weave |

Weight (g/m2) |

Mullen burst (kpa) |

Tensile strength (N/2.5cm) |

Air permeability(cm3/cm2/s·127pa) |

Finished |

Running temperature

(°C) |

| warp |

weft |

| FA301 |

> 10 |

double twill |

780-850 |

> 6200 |

> 2400 |

> 2000 |

15-30 |

PTFE |

<260 |

| FI301 |

> 10 |

double twill |

780-850 |

> 6200 |

> 2400 |

> 2000 |

15-30 |

PI |

<260 |

| FB302 |

> 2 |

1/3 twill |

450-500 |

> 4500 |

> 2000 |

> 1200 |

20-36 |

PGS |

<260 |

| FC302 |

> 5 |

1/3 twill |

340-380 |

> 4500 |

> 2000 |

> 1200 |

20-36 |

AR |

<260 |

| FA303 |

>10 |

1/3 twill |

320-360 |

> 3500 |

> 1400 |

> 800 |

22-35 |

PTFE |

<260 |

| FC303 |

> 5 |

1/3 twill |

900-950 |

> 3400 |

> 1200 |

> 700 |

22-35 |

AR |

<260 |

| FD502 |

> 7 |

satin |

900-950 |

> 8000 |

> 3000 |

> 2400 |

15-25 |

PD |

<400 |

| FA404 |

> 10 |

double twill |

800-850 |

> 5000 |

> 2600 |

> 2200 |

15-30 |

PTFE |

<260 |

| FE201 |

>1.7 |

satin |

550-600 |

> 5500 |

> 2200 |

> 2000 |

20-35 |

PG |

<260 |

| FE203 |

> 1.7 |

1/3 twill |

550-600 |

> 5500 |

> 2200 |

> 2000 |

20-35 |

PG |

<260

|

Notices:

glass fiber needle felt is one kind of high temperature resistant filter material with reasonable structure and excellent performance,it could be high temperature resistant,anti-abrasion,stable size,little elongation shrinkage ratio,high intension,also ultimate fiber of felt layer fiber,three dimensional micro pore structure,high porosity,small filter resistance to gas,it has higher speed and efficiency,Comparing with other high temperature resistant chemical fiber felt,it has the advantage of lower price,high temperature resistant,but due to high resistance, filtering efficiency is lower

Applications:

Chemical plant Cement plant

Steel iron plant Melting plant

Carbon black plant Electricity Industry

Hangzhou philis filter technology co.,ltd. has grown up to be one of leading manufacturer on dust filtration&spare parts in China.We have imported filter needle felt production line ASSELIN from France and we can produce very good quality non-woven products according customer's requirment.

Based on 8 needle felt production line ,our annual production ability can achieved 20,000 square meters per day . We can produce a large range of various filter fabric, such as polyester filter fabric, Acrylic filter fabric, Fiberglass filter fabric, PPS filter fabric, Nomex ,P84 ,PTFE ,woven filter fabric and so on.

The most important thing is that we introduced German high technology to develop the first filter bag production line in China. Which help most filter bag production factory save a lot of human lab our cost but promote the work effection . The advanced technology and simple operation way of automatic filter bag production line has won a lot of customer’s praise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!