Specifications:

| Product name |

Polyamide filter fabric for dust collection bag for chemical |

| Model No. |

PA4 |

| Material |

Polyamide(Nylon) |

| Color |

Customized color |

| Size |

Customized size |

| Weight |

400 gsm |

| Thickness |

0.5-1.0mm |

| Certificate |

ISO9001 |

| Technology |

Single weave |

| Weave |

Plain |

| Filter cloth type |

Monofilament |

| Type |

Liquid-solid filter/ Dust removal/ Dry filter |

| Application |

Sludge dewatering/ Chemical/ Dust |

| Characteristic |

Anti-alkali , Low temperature resistance |

| Running temperature(℃) |

120 |

| Instant temperature(℃) |

135

|

Woven nylon 6 industrail filter fabric

| Item Name |

Density

warp/weft (10cm)

|

Weight

g/m2

|

Airpermeability

(10-3m3/m2.s)

|

material |

Fabric texture |

| 3110 |

700/196 |

405 |

210 |

Monofilament |

stain |

| 6235 |

354/161 |

400 |

210 |

Monofilament |

stain |

| 2475 |

945/295 |

600 |

85 |

Monofilament |

Changes in organization |

| 856 |

290/126 |

446 |

80 |

filament |

twill |

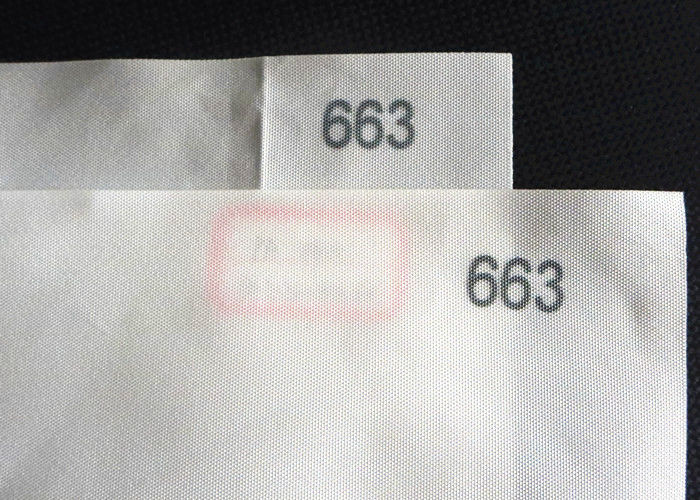

| 663 |

192/140 |

265 |

30 |

filament |

plain

|

Application:

Chemical:

Catalyst, cobalt carbonate, zinc oxide, zirconium carbonate, activated carbon, cobalt carbonate, borate, dyes and intermediates, iron oxide, nickle, salt, aluminum oxide, titanium dioxide, additives, glycerol, pesticides, white carbon black, zinc, calcium carbonate, etc.

Mining:

Red mud, tailings gold, potash fertilizer, vanadium ore, the end of coal, clean coal, clay, Kaolin clay, etc.

Metallurgical:

Gold, molybdenum, lead, vanadium, nickel, zinc, copper, tungsten, carbide slag, etc.

Food:

Fruite juice, suger, starch, sweetener, beer, etc.

Environmental protection:

Sewage treatment, slude dewatering, flue gas desulphurization, salt mud, fly ash, etc.

Hangzhou philis filter technology co.,ltd. has grown up to be one of leading manufacturer on dust filtration&spare parts in China.We have imported filter needle felt production line ASSELIN from France and we can produce very good quality non-woven products according customer's requirment.

Based on 8 needle felt production line ,our annual production ability can achieved 20,000 square meters per day . We can produce a large range of various filter fabric, such as polyester filter fabric, Acrylic filter fabric, Fiberglass filter fabric, PPS filter fabric, Nomex ,P84 ,PTFE ,woven filter fabric and so on.

The most important thing is that we introduced German high technology to develop the first filter bag production line in China. Which help most filter bag production factory save a lot of human lab our cost but promote the work effection . The advanced technology and simple operation way of automatic filter bag production line has won a lot of customer’s praise.

Service:

PRE-SALE SERVICE

Detailed, professional and complete analysis can help customers with best possible understandings of their applications and requirements. Then best-use technical solutions are provided.

SALES SERVICE

With excellent language skills, our sales people can communicate well with customers from all of the worlds.

With many years experiences of import and export, our sales people are very familiar with international trade flow. These can help customers to save cost and avoid the risk.

With high responsibility, our sales people make your prompt response anytime and help you follow up the production, packing and delivery time.

AFTER SALES SERVICE

Provide customers with technical supervision for filter bag installation.

Provide customers with regular laboratory tests to monitor system and filter bag performance.

Provide customers with accurate and detailed filter bag failure analysis reports and system improvement recommendations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!