Custom Metal Venturi Air Filter Cage for Dust Collector Filter Bags Carbon Steel

Quick Detail:

1. Ventury filter cages -ISO9001:2008 Certified

2. Carbon or stainless steel

3. Galnanized or silicon plated surface

4. Any size

Description:

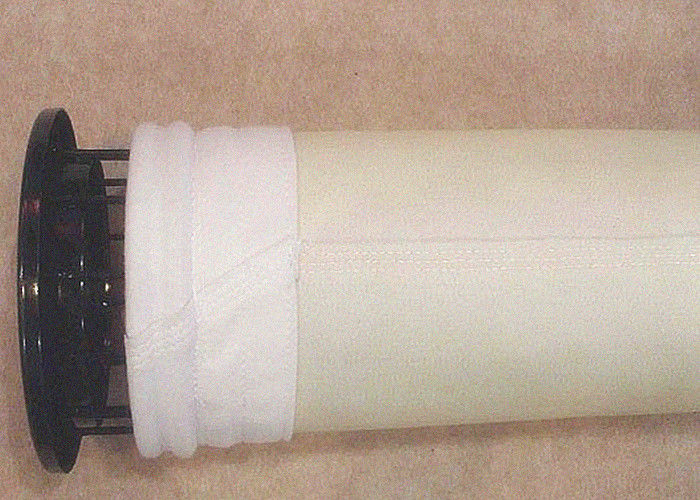

bag Filter cage with Zinc galvanized Surface Finish

using the advanced hot-melt jointing technology. The jointing method of bag bottom, side and collar ring all are hot-melt welded, that can avoid the pinholes from seam filter bag.

The Filter bag cage is a rib filter cage and it should be light and easy for installation and maintenance. The quality of a cage has directly bearing on the filtering state and service life of a filter bag. Every cage we make can meet the requirement for tightness, smoothness and uprightness.

Specifications:

Ventury filter cages

The ventury filter cages from China manufacturer is a rib of a filter bag and it should be light and easy for installation and maintenance. The quality of a cage has directly bearing on the filtering state and service life of a filter bag. Every cage we make can meet the requirement for tightness, smoothness and uprightness.

1. material of cage: carbon steel / SS304, 316, 316L

2. type of cage: any type

3. type of the horizontal bar: Any type

4. surface treatment: Galvannized or silicon power plated

The vertical bar, horizontal ring, spacing ring, length, the diameter of the ring and the shape of the cage can be according with the requirement from client.

The thichkness of the longitudinal wire can be Φ3, 3.2, 3.5, 3.8, 4.

Notices:

We make filter cages of different shapes and dimensions to meet customers’ requirements. To supply with perfect testing for our products. Our cost is under utmost lower control because of our assembly line production. Precise, pragmatic and prudent working styles are adopted in every working procedure at CNP. We are highly responsible for every product component In addition, advanced manufacture equipment and scientific management made each finished product become the first selection of customers. By offering reliable assurance to integrate product quality with international standards with advanced equipment and technology, Professional production of dust cage skeleton, and can also design, develop, and manufacture as the clients request.

Specification

The Mian Specification Parameters of The Bag Cage

| Type |

Circle type,Oval type,Flat type,Special-shaped |

| Material |

Carbon steel,Galvanized steel wire,Stainless steel,Titanium wire |

| Finish treatment |

Galvanized,organic silicon spray,anti-corrosion treatment |

| The number of lingitudinal bar |

8~24 wires(Circle Type),10~16 wires (Oval Type) |

| Structure |

Single section type bag cage,screw joint type,double wire PJE type,single wire PJE type,etc |

| Configuration |

Venturi,protection nozzle stub |

|

Goods Name

|

Standard

|

Description

|

Goods Name

|

Standard

|

Description

|

|

Clamps

|

φ180

|

|

Spring curb

|

120*2

|

Normal quenching steel belt

|

|

φ230

|

130*2

|

|

φ250

|

150*2

|

|

φ260

|

200*2

|

|

φ292

|

292*2

|

|

φ300

|

300*2

|

|

Hoop

|

φ160

|

φ300-φ270 using wire rod ofφ4.2

|

120*2.5

|

|

φ170

|

130*2.5

|

|

φ180

|

150*2.5

|

|

φ200

|

182*2.5

|

|

φ210

|

202*1.3

|

Quenching stainless steel belt

|

|

φ250

|

φ180 using wire rod of φ3.3

|

127*1.5

|

|

φ260

|

127*1.9

|

If it is highly corrosive, we can use titanium curb

|

|

φ280

|

130*2.5

|

|

φ292

|

φ260-φ180 using wire rod of φ3.8

|

150*2.5

|

|

φ300

|

129.6*2.5

|

|

φ400

|

280*2

|

|

φ615

|

Pendant chain device

|

Hung huang, pendant chain

|

|

|

Cap

|

180

|

upper cap lower cap

|

|

200

|

|

230

|

Venturi tube

|

Carbon steel

|

|

250

|

Aluminum

|

|

292

|

Stainless steel

|

|

300

|

Unifying covering cap and venturi tube(integration)

|

|

Filter cage

|

Material: hard-drawn wire

|

Galvanization treatment

|

Normal

|

Yellow

|

|

White zinc plated treatment

|

High quality

|

Light silver

|

|

Organic silicon treatment

|

|

Black

|

|

Material: stainless steel

|

201-316L

|

|

|

|

Any special requirement and production can be processed according to buyer’s sample(with drawing)

|

Applications:

Power Stations

Filtered dust

Flue ash, discharging flue ash

Coal dust

Building and Construction

Cement, furnace dust, gypsum, limestone, finely ground quartz,

Calcium hydroxide, lead monoxide, quicklime, acid crystals,

Pure clay, phosphates, magnesite concentrate, finely ground

fluorid, production of aluminum

Chemical Industry

Thomas meal (Fertilizer)

Rubber compounds, sinter dust, catalysts

Sodium sulfate

Soap powder

Hangzhou philis filter technology co.,ltd. has grown up to be one of leading manufacturer on dust filtration&spare parts in China.We have imported filter needle felt production line ASSELIN from France and we can produce very good quality non-woven products according customer's requirment.

Based on 8 needle felt production line ,our annual production ability can achieved 20,000 square meters per day . We can produce a large range of various filter fabric, such as polyester filter fabric, Acrylic filter fabric, Fiberglass filter fabric, PPS filter fabric, Nomex ,P84 ,PTFE ,woven filter fabric and so on.

The most important thing is that we introduced German high technology to develop the first filter bag production line in China. Which help most filter bag production factory save a lot of human lab our cost but promote the work effection . The advanced technology and simple operation way of automatic filter bag production line has won a lot of customer’s praise.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!