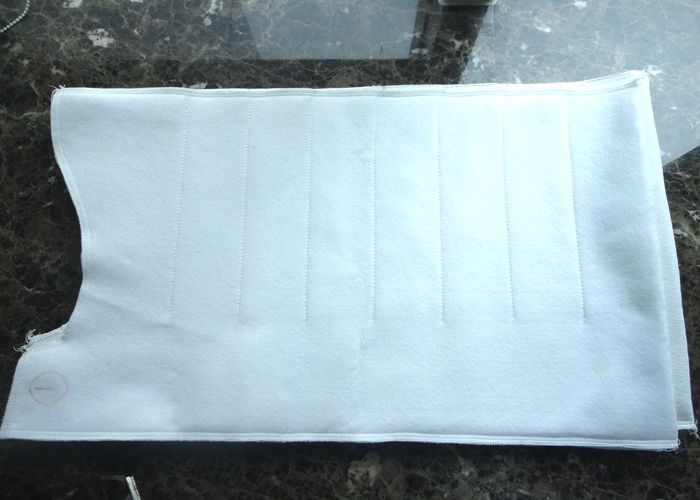

liquid filter bag / metal machining liquid filter bag / micron filter bag

Quick Detail:

Material : PP or PE,polyester, polypropylene

Micron rating : 0.5um ~800um

Good anti-abrasion

High temperature grade

Anti-acid ,anti-alkali, chemical resistance

High porosity ,good air permeability

Laminated compound,grads counterchange

Description:

Polyester fiber and non-woven needled felt filtration material made of it

Polyester needled filtration felt is made by polyester fiber and the fabric woven high-strength, low-elongation yarn. The Dacron fibers are needled noto the fabric by needled-punching machine.

Polyester fiber has low absorption of humidity. The water regain rate under standard condition is 0.4-0.5%,while 0.6-0.8% under the condition of relative humidity 100%. Therefore, the fiber will keep almost the same properties in both dry and wet conditions. It shows good resistance for almost all the atmosphere under the room temperature. The strength of the polyester is high and the elastic recovery performance is good. The strength of it is 3.52-5.28CN/dtex, elongation at break is around 30-40%.

The polyester has good size stability, high strength, high elongation and good elastic recovery performance. So that, the polyester fabrics fabrics has good abrasion resistance. The glass transition point of polyester fiber is 80℃,melting point is 255℃~265℃. It starts to become soft at 230℃~240℃. Polyester fiber has very good application function under room temperature. It is the most reasonable filtration materials for the industry conditions with common temperature.

This product has the advantages of high porosity, good permeability, good abrasion resistance and resistance to acid. The consumption amount of polyester is the biggest among the needled felt filtration material. It is widely used in the fields of metallurgical, chemical, building materials, metallurgy, power generation, ceramics, machinery, mining, petroleum, pharmaceutical, food, dye, mining etc. It is currently the most ideal filtration materials for the common temperature conditions.

Specifications:

#1-----(7"x16") -----¢180*410mm

#2-----(7" x 32") -----¢180*810mm

#3-----(4"x 8 1/4") -----¢102*210mm

#4-----(4"x 14") -----¢102*356mm

| Material |

PE,PP,NMO,PTFE |

| Cuff |

PP Lock, Stainless steel |

| Relative filtration pore size |

0.5, 1,5, 10, 25, 50, 100, 200 µm |

| Type |

various specifications |

| Airtight method: |

Hot Melt, reverse sewing |

| Effective filtration area |

various specifications |

| Others |

special requirement of diameter and collar extension can be customized |

Notices:

1. Materials avaliable: polyester, polypropylene

2. construction: welded or sewn

3. collar type: steel ring or plastic ring

4. finishing treatment: singed, calendared, heat set

5. Size available: standard and custom size.

Applications:

1. Paints & lacquer industry

2. Wastewater treatment

3. Pharmaceutical industry

4. Food industry

5. Chemical industry

6. Beer, wine & spirit industry

7. Adhesive.

Hangzhou philis filter technology co.,ltd. has grown up to be one of leading manufacturer on dust filtration&spare parts in China.We have imported filter needle felt production line ASSELIN from France and we can produce very good quality non-woven products according customer's requirment.

Based on 8 needle felt production line ,our annual production ability can achieved 20,000 square meters per day . We can produce a large range of various filter fabric, such as polyester filter fabric, Acrylic filter fabric, Fiberglass filter fabric, PPS filter fabric, Nomex ,P84 ,PTFE ,woven filter fabric and so on.

The most important thing is that we introduced German high technology to develop the first filter bag production line in China. Which help most filter bag production factory save a lot of human lab our cost but promote the work effection . The advanced technology and simple operation way of automatic filter bag production line has won a lot of customer’s praise.

FAQ

1.What is your time of making samples?

Usually we will take around 3-5 days to make the samples.

2.What is your MOQ?

Our MOQ is usually 1 carton.

3.What is your delivery time?

The time of delivery is about 7-15 days.

4.What is the loading port?

Ningbo/Shanghai

5.What is your payment terms? (Total amount > USD$10,000)

We accept 30% T/T in advance,70% before shipment.

6.What is the location of your company?

Our company is located in Zhejiang.

7. How about the samples?

We could send you the samples but the samples are charged.After the order is

confirmed, we would pay back the sample fee. Please be rest assured of that.

Essentially we sometimes send the samples for free.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!